3D Printing Fume Extractor

Parameters of VHICH Series Automatic Cleaning Type Industrial Dust Collector

| 《SC: stands for Shengchuan, T8: product series, A: stands for economic type, 55: power 5.5kw, L4: stands for 4 filter cartridges, X: stands for frequency conversion control》 | |||||||||

| Serial number | Device Name | Slanted filter cartridge dust collector | Slanted filter cartridge dust collector | Slanted filter cartridge dust collector | Slanted filter cartridge dust collector | Slanted filter cartridge dust collector | Slanted filter cartridge dust collector | Remark | |

| 1 | Device Type | Economical | Economical | Economical | Economical | Economical | Economical | ||

| 4 | Device Model | SCT8-A30L2 | SCT8-A55L4 | SCT8-A75L6 | SCT8-A110L8 | SCT8-A150L9 | SCT8-A185L9 | ||

| 5 | Equipment power | 3KW-4/KW | 5.5/KW | 7.5/KW | 11.0/KW | 15.0/KW | 18.5/KW | ||

| 6 | Supply voltage | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz | ||

| 8 | Fan brand | Shengchuan Brand | Shengchuan Brand | Shengchuan Brand | Shengchuan Brand | Shengchuan Brand | Shengchuan Brand | Own brand French technology | |

| 9 | Air volume | 3000-4000㎥ /h | 4000-5000㎥ /h | 5500-6000㎥ /h | 6000-9000㎥ /h | 9000-11000㎥ /h | 11000-13000㎥ /h | ||

| 10 | Fan static pressure | 2800-3200Pa | 2800-3200 | 3000-3300 | |||||

| 11 | Control System | 4.3-inch touch screen + intelligent PLC (Chinese and English version) | 4.3-inch touch screen + intelligent PLC (Chinese and English version) | 4.3-inch touch screen + intelligent PLC (Chinese and English version) | 4.3-inch touch screen + intelligent PLC (Chinese and English version) | 4.3-inch touch screen + intelligent PLC (Chinese and English version) | 4.3-inch touch screen + intelligent PLC (Chinese and English version) | Independently developed intelligent control/expandable functions | |

| 12 | Filter cartridge specifications | Small hole single pass/quick release 325*660mm/2 pieces | Small hole single pass/quick release 325*660mm/4 pieces | Small hole single pass/quick release 325*660mm/6 pieces | Small hole single pass/quick release 325*800mm/6 pieces | Small hole single pass/quick release 325*800mm/9 pieces | Small hole single pass/quick release 325*1000mm/9 pieces | ||

| 13 | Filter area | 35-40㎡ | 75-80㎡ | 115-120㎡ | 145-165㎡ | 215-220㎡ | 272-285㎡ | ||

| 14 | Filtration efficiency | 99.90% | 99.90% | 99.90% | 99.90% | 99.90% | 99.90% | ||

| 15 | Filter level | (H13)/F9 | (H13)/F9 | (H13)/F9 | (H13)/F9 | (H13)/F9 | (H13)/F9 | ||

| 16 | Remote Control | Linkage/Start/Stop | Linkage/Start/Stop | Linkage/Start/Stop | Linkage/Start/Stop | Linkage/Start/Stop | Linkage/Start/Stop | Optional frequency conversion energy saving package to reduce energy consumption | |

| 18 | Filter cartridge material | PTFE polyester coating/nano coating flame retardant-(standard) | Polyester material can be selected according to working conditions | ||||||

| 19 | Drive motor | (Shengchuan’s own brand) – (standard configuration) | |||||||

| 20 | Differential pressure monitoring | (Monitor real-time pressure difference)-(Standard) | Dust removal performance through pressure difference | ||||||

| 21 | Alarm buzzer | (Operation stop warning buzzer) – (Standard) | |||||||

| 22 | Temperature monitoring | (Monitoring equipment and dust temperature warning) – (standard) | Effectively prevent dust collector combustion risks | ||||||

| 23 | Pulse cleaning | (Automatic intelligent dual mode)-(Standard) | Energy saving based on pressure difference and timing mode | ||||||

| 24 | Flame Arrester | (Stainless steel wire mesh fire barrier)-(standard) | Prevent high temperature sparks from entering the equipment | ||||||

| 25 | Air Inlet | Upper air inlet device + plate type flame arrester | |||||||

| 32 | Equipment noise | 65dB±5 | 70dB±5 | 70dB±5 | 70dB±5 | 72dB±5 | 72dB±5 | ||

| 33 | Ash collection capacity | 45L | 48L | 50L | 50L | 55L | 60L | ||

| 34 | Equipment Net Weight | 300kg | 450kg | 580kg | 730kg | 930kg | 1080kg | ||

| 35 | Overall dimensions (mm) | 1700*940*1933=3.4m³ | 1750*1100*1933=4.1m³ | 1872*1100*2245=5.1m³ | 1870*1100*2500=5.6m³ | 1870*1445*2500=7.4m³ | 2100*1445*2500=8.3m³ | Maximum size of packing box cubic | |

Thermal cutting dust control

With the continuous development of science and technology and the increasing degree of automation, production technologies such as flame cutting, plasma cutting, and laser cutting have been continuously improved and popularized. However, these high-efficiency production technologies have also brought about increasingly serious pollution problems, resulting in greater smoke and dust in the workplace, so a special dust collector for thermal cutting is essential. Shengchuan Environmental Protection has rich experience in products and technologies for dust removal in the field of thermal cutting. After more than ten years of accumulation, it provides customers with the most practical special machine solutions and a complete product line, which can be applied to multiple fields and industries.

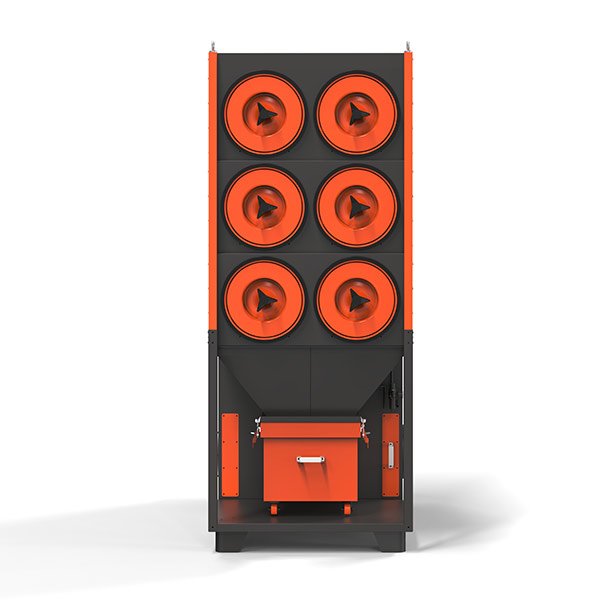

SCT8-A Series Slant Insertion-Cartridge Dust Collector

Shengchuan SCT8-A series oblique filter cartridge dust collector is a dust removal and purification product developed to solve the problem of large amounts of dust and smoke generated during mechanical processing in industries such as laser cutting machines, laser tube cutting machines, plasma cutting machines, and metal grinders in the current market.

How it works

The dusty flue gas generated during the production process enters the dust collector through the air inlet. The dusty flue gas is forced downward and passes through the filter cartridge. The dust or smoke is collected on the surface of the filter material. The pulse cleaning system distributes the compressed air to the filter through the pulse valve in turn, so that the dust or smoke on the filter falls off from the surface of the filter cartridge, thus forming clean air for direct discharge.

High static pressure fan

Specially designed for thermal cutting dust removal, French fan technology, multiple blades, low noise, high static pressure, making dust removal more efficient

Low noise design

Self-developed silent integrated fan, using German technology, high-performance fan installed at the bottom of the device to maximize noise control

Cutting dust filtration

For thermal cutting dust, high-temperature resistant and high-precision coating technology is used, which is very different from ordinary filtration and is more efficient in high-speed pulse airflow cleaning.

Differential pressure monitoring

The dust removal performance is realized through the pressure difference. Imported chips, wide pressure precision design, sampling speed 20 times/second, stable and fast output

PT temperature control monitoring

The temperature monitoring system detects and records the equipment temperature in real time to ensure that it operates within the appropriate range, prevents overheating and damage to the equipment, and effectively prevents the risk of dust collector combustion.

Plate type flame arrester

Metal stainless steel wire mesh fire-blocking plates are installed at the air inlet and outlet of the equipment to effectively prevent high-temperature dust and sparks generated in some high-temperature environments from entering the equipment cavity and causing the risk of equipment combustion or explosion

Downdraft dust removal system

Adopting a number of technological innovations, the smoking effect is remarkable, the installation and maintenance are simple, and it is economical and energy-saving. The effect of cutting smoke absorption and purification depends largely on the design of the dust-collecting cutting table. In order to maximize the smoke absorption rate, the dust-collecting cutting table adopts a modular design. No matter what the cutting range of your cutting machine is, we can Modular combinations to the size you need. The interior of the partitioned cutting table is divided into multiple independent areas for separate segmented dust collection. Each independent area has an independent valve, and is controlled by the cutting machine to automatically open the air valve in the area where the cutting is performed for smoking and dust removal. Each suction area in the lower part is equipped with a dust collection box to facilitate lifting and dumping of dust.

Partitioned dust removal systems are mostly used in laser cutting machines and flame cutting machines.

Pipe cutting dust removal system

Pipe cutting mainly involves cutting off pipes and processing intersection lines. Pipes are generally long and thick, and produce a large amount of smoke and dust. This type of cutting machine generally uses a dust removal method that directly extracts air from the chuck port of the cutting machine. When the cutting head cuts more bevels, more smoke and dust will overflow. At this time, it is best to add an air suction device above the cutting head to ensure the dust removal effect.

Pipe cutting dust removal systems are mostly used in intersecting wire cutting machines, laser pipe cutting machines , etc.

Side suction dust removal system

The side suction dust removal system is to place a square suction duct on one side of the cutting platform, on which there is a suction port that can move with the cutting machine, and on the other side of the cutting platform there is a blowing port with a small axial flow fan. The suction port and the blowing port are fixed on the cutting machine at the same time and are kept in line with the cutting head; or a square suction duct is placed on both sides of the cutting platform, on which there is a suction port that can move with the cutting machine, and the suction port is fixed on the cutting machine at the same time and is kept in line with the cutting head; the lower part of the cutting platform is an exhaust duct with a vertical plate, which always keeps exhaust only within the limited width of the cutting, that is, the part where smoke and dust are generated. When working, the sealing belt is tightly attached to the top of the square suction duct under the action of the negative pressure of the pipeline, which plays a sealing role. There are two rollers in the suction port, and the sealing belt is lifted up here, so that the smoke and dust enter the suction duct through the suction port and are finally sucked into the dust removal equipment for filtration and purification.

Side suction dust removal systems are mostly used in gantry plasma and flame cutting machines.

For the working conditions where one steel plate or two steel plates are placed closely side by side, the blowing and suction type is generally an economical and effective way of smoking.

For working conditions where large width cutting and steel plates cannot be placed close together, the double suction type is generally a more effective way to smoke.

Side suction dust removal system

The blowing-suction type only needs to install a side suction port on one side of the gantry and an air supply fan on the other side, which means that only one air duct (occupying about 500mm of space) is required, which takes up less space in the gantry. For the same effective cutting area, the gantry can be smaller. At the same time, the air volume required for the cutting table is also smaller, and the equipment investment and operating costs of the purifier are also reduced. The double-suction type requires double air ducts and double suction ports on both sides of the gantry. The air duct occupies 500×2=1000mm of space. Sometimes, due to limited space in the guide rail, it can be considered to be placed on the outside of the gantry. The double-suction type is also a water injection type, and the air suction volume required for the double-suction type is almost twice that of the blowing-suction type.

When the effective cutting width of a double-gantry blowing-suction cutting machine is less than 5 meters, it is recommended to use a blowing-suction dust removal system.

When the effective cutting width of a double-gantry double-suction cutting machine is greater than 5 meters, it is recommended to use a double-suction dust removal system.

Operation interface, supports multiple languages

VHICH independently develops a fully intelligent control unit, which is specially developed and designed for the field of thermal cutting machines. The parameter settings are intuitive and clear, and the operation is simple. It can be operated intelligently according to the working conditions to ensure the normal operation of the dust collector. It can be connected to the main equipment switch signal to remotely control the machine operation and stop as well as the energy saving package. The display supports Chinese, English, German, Japanese, Korean, Russian and other languages.

Shengchuan believes that truly effective smoke and dust control is not simply to provide a set of general dust removal equipment. Choosing the right dust removal equipment can take into account both efficient filtration and reduced energy consumption.

Shengchuan specializes in producing cartridge dust collectors for various fine dusts such as metal thermal cutting, welding, grinding and machining.

Related products

Want To Find Out More About VHICH Industrial Dust Collector?

Fill in your details and query below, and we will be in touch.